Creating a New Business Card for China Green Intelligent Manufacturing, TCL CSOT Launching the Industry's First White Paper on Carbon Neutrality

Global warming has become a serious challenge for human society, and "carbon neutrality" is one of the best solutions to this challenge. Recently, TCL CSOT, the leader of semi-conductor display, with China Video Industry Association and China National Institute of Standardization, jointly published the first White Paper on Carbon Neutrality of China's Semiconductor Display Industry to explore how semi-conductor display enterprises can achieve the goals of ecology priority and quality, green and low-carbon development through scientific and technological innovation and building life-cycle green and low-carbon management.

The White Paper on Carbon Neutrality of China's Semiconductor Display Industry shows the global carbon emission status and China's carbon peaking and carbon neutrality goals, and combs the development and carbon emission status of China's semi-conductor display industry.

The White Paper points out that the "carbon neutrality" road is not only a challenge faced by the industry, but also a historical opportunity for enterprises to improve their competitiveness and achieve their own sustainable development. Semi-conductor display enterprises urgently need to respond with scientific and technological innovations, promote the application of low-carbon technology in the whole process, build a life-cycle green and low-carbon management, form the resource-saving and environmental industrial structure, production mode and spatial pattern, continuously explore and accumulate in practice, and contribute to the implementation of China's great "carbon neutrality" strategy. In addition, the White Paper also shows the measures and efforts of the leading enterprise in reducing carbon, which provides a detailed reference for the carbon neutrality path of the semi-conductor display industry.

TCL CSOT Making a Move for "Zero Carbon" to Achieve Green Production in a Multi-pronged Approach

How to achieve low-carbon production is a difficult problem that many enterprises must face directly. TCL CSOT, as the "carbon neutrality leader" in the semi-conductor display industry, provides a feasible solution. TCL CSOT always adheres to the green development and explores the way forward to deepen corporate social responsibility. At the same time, it continuously improves the environmental information disclosure, improves the efficiency of energy use, and persists in low carbon emission reduction in production and operation through technological innovation, green factories and energy conservation renovation projects to help achieve the green development goals.

In order to reduce energy consumption and promote green development, TCL CSOT attaches great importance to the construction and application of green energy mainly based on solar energy. Using the existing roofs in the factory, TCL CSOT has built the largest photovoltaic power generation system in industrial parks in South China with an installed capacity of 39.46MW; the power generated by it can reach 40 million KWH per year; and the amount of energy saved per year equals to the daily energy consumption of 200,000 households. It greatly reduces the use of fossil energy and further optimizes the structure of energy use.

On the other hand, TCL CSOT attaches great importance to energy recycling in the production process. In the production process of LCD panel display, in order to ensure product quality, a large amount of pure water is usually used for cleaning. Therefore, TCL CSOT has established a pure water recycling system. According to the nature of recyclable wastewater, the pure water recycling system can recycle about 34.6 million cubic meters of pure water annually, save about 172 million Yuan on tap water, and greatly improve the utilization rate of water resources.

TCL CSOT also achieves an annual average reduction of energy consumption of about 450KWH, a reduction of greenhouse gas emissions of about 1700 tons, and an annual resource recovery and utilization of about 67,000 tons through the implementation of energy saving and consumption reduction projects such as “wind-water co-creation", waste reduction and resource utilization, which greatly improves the resource recovery and utilization rate.

Through a series of practical and effective carbon reduction measures, TCL CSOT gradually built a complete green production system, and has been highly recognized. In 2019, TCL CSOT Wuhan t4 project won the highest international standard "LEED" platinum level certification in green building and China Green Building Three-star Certification. In 2021, TCL CSOT t6t7 project became a Green Building Three-star Twin Star Factory and won other honors, which is closely related to TCL CSOT's concept and action of carbon reduction and environmental protection.

Innovation of Product Technology Delivering A Scientific & Technological Green Answer

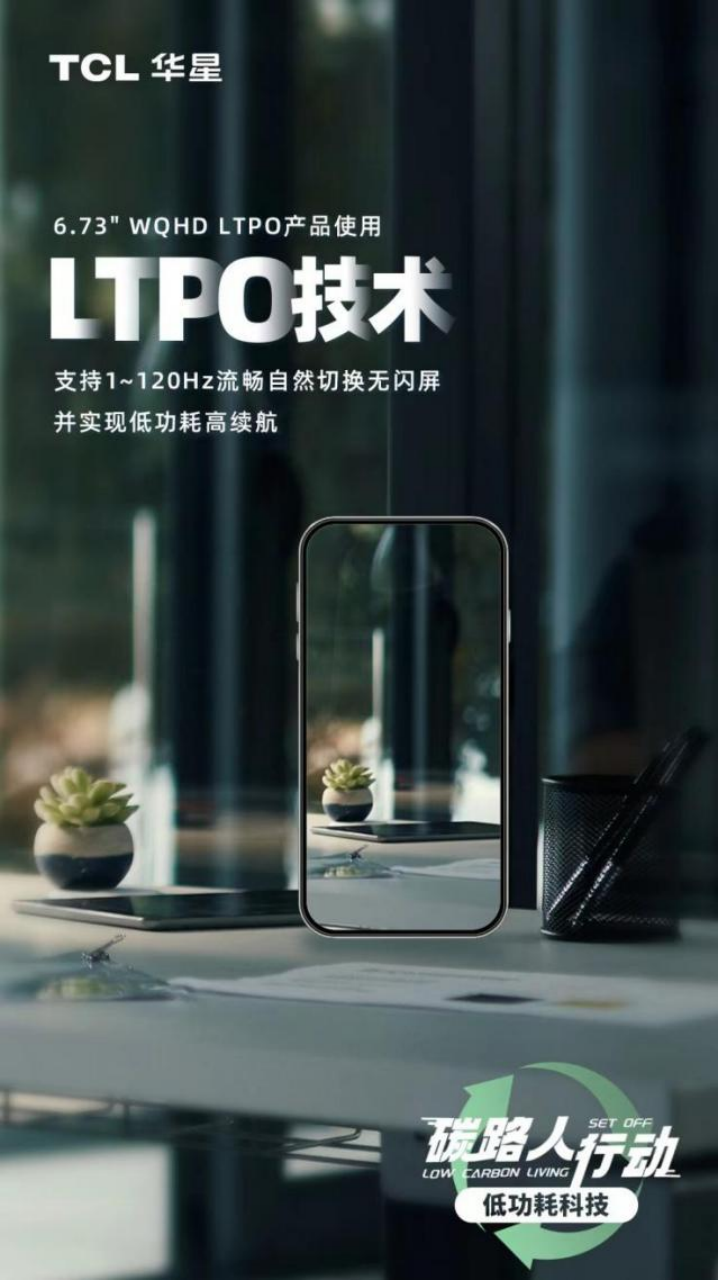

In product technology, TCL CSOT adheres to the development and production of green products, and continuously reduces energy consumption of products without reducing performance, in which, LTPO and broadband LTPS are the two technologies which are worth being mentioned.

LTPO, as a low-power display technology, has aroused wide concern in the industry. TCL CSOT’s LTPO technology can support 1-120Hz smooth and natural switching without flickering, greatly improve the visual effect and reduce power consumption. In addition to adaptive refresh rate, there is also a combination of direct frequency conversion technology + WQ LTPO + MLP (Micro Lens Panel) with low power consumption. Compared with the original LTPO, after integrating direct frequency conversion technology, TCL CSOT makes device frequency switching faster and smoother, matching the appropriate refresh rate according to the content of the picture display in time to save power consumption.

If LTPO low frequency display technology is the current mainstream technology, the broadband LTPS takes a different approach. Based on the conventional LTPS, through design, drive and process optimization, LTPS display can achieve the display effect of a refresh rate less than 30Hz, low flicker and low power consumption. With the introduction of broadband LTPS technology, the dynamic frame-frequency switching display of 10-480Hz can be achieved according to different scenarios to save energy and power.

Based on LTPS-TFT technology, TCL CSOT also integrates ambient light and color temperature sensors in the electronic device screen, which enables real-time monitoring of ambient light illuminance and color temperature; at the same time, the screen brightness can be adjusted adaptively according to the ambient brightness, which not only provides a more comfortable visual experience, but also further reduces the power consumption of the product.

TCL CSOT has established a set of its own green technology standards through green intelligent transformation and product technological innovation, and has been recognized by many parties. Lin Ling, President of Resource and Environment Branch of China National Institute of Standardization, also indicated in the White Paper that technological standard is a way to mitigate and adapt to climate change. Achieving energy conservation and consumption reduction in semi-conductor industry by using renewable energy, improving production efficiency, promoting process upgrade, optimizing production processes, etc. is of great significance to achieve carbon neutrality goals.

In the future, TCL CSOT will continue to implement the concept of low-carbon, and further build an industrial ecology supported by green low-carbon development through technological innovation to boost "carbon neutrality" and "the creation of a better world", and to enable China's panel display industry to become a new business card of green, intelligence and efficiency.