Which one is better with Mini LED backlight technology? TCL CSOT quickly stands out from the industry

In recent years, with the increasing popularity of Mini LED backlight technology on the market, manufacturers of various brands are also optimistic about the application and growth potential of Mini LED, accelerating the pace of seizing this core track.

Driven by many industrial giants, the market size of Mini LED industry has rapidly increased. According to the In-depth Research and Development Prospect Analysis Report of China’s Mini LED Industry Market from 2021-2026 published by Zero Power Intelligence, the global market size of Mini LED will increase from USD 150 million dollars to USD 2.32 billion, with an expected annual year-on-year growth rate of more than 140%. In the next few years, the application of Mini LED in display will have explosive growth from 0 to 1.

So, why is Mini LED backlight technology so popular?

What is Mini LED backlight technology

Today, OLED screens have not been fully popularized, and LCD screens are still the main display devices we contact daily, while Mini LED, as a backlight application, has many advantages such as high brightness, high contrast, low power consumption, and so on. It is increasingly concerned and favored in the LCD display field.

Mini LED, also known as submillimeter LED, mainly refers to the LED device with the chip size between 50-200 μm. The improvement direction of Mini LED backlight technology is to reduce the area of partitions and increase the number of partitions, so that the panel can display a more delicate Local Diming effect when the area is unchanged. With the progress of backlight technology, the standard size of grain and screen contrast of Mini LED has achieved leapfrog development.

Two types of mainstream Mini LED backlight

At present, there are two main types of mainstream Mini LED backlights: PM Mini LED backlight and AM Mini LED backlight. The PM mode is mainly based on the PCB board, and uses the Driver IC to realize the single area control of backlight. The AM mode is mainly based on the glass substrate, and uses the TFT drive control to realize the single area control of backlight.

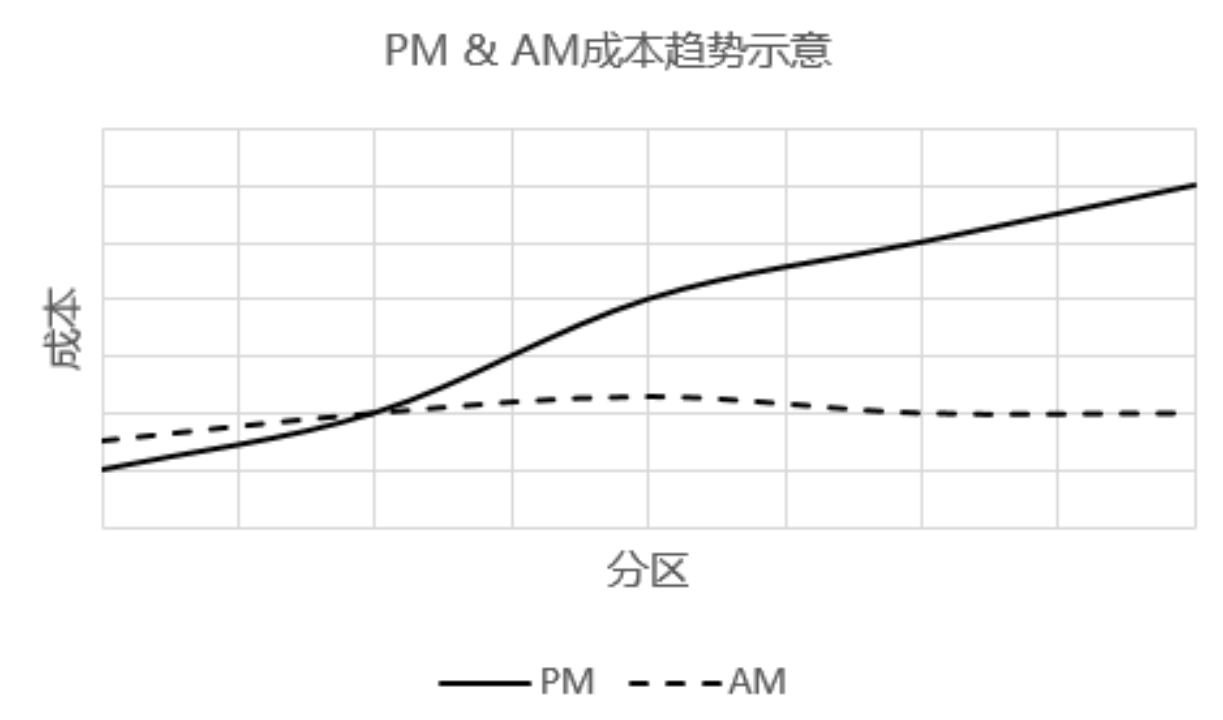

The backlight technology developed by PM Mini LED has achieved mass production at this stage, but due to the limitation of drive design, the number of partitions is small, which limits the optimization of backlight structure, resulting in poor viewing experience of picture details, becoming the pain point of this technology. Basically, the PCB/FPC substrate is used in this scheme, and the cost of the substrate itself is high. In addition, the expansion and contraction of the substrate bring about the influence of the yield of solid crystal, bonding, etc., which leads to the high overall cost of backlighting.

For AM mode, the glass itself has the advantages of low shrinkage, low warpage, high temperature resistance, etc. At the same time, through the thinning process, it can achieve the same thickness as the ultra-thin PCB substrate, which is very suitable for use as the substrate of Mini LED, and can achieve ultra-high partition design. At the same time, the cost does not increase significantly with the increase of partition number.

Technical advantages of TCL CSOT's AM Mini LED

Facing the huge market prospect of Mini LED backlight technology, TCL CSOT developed AM Mini LED backlight based on LTPS substrate in combination with small and medium-sized product types. This backlight technology has obvious performance and cost advantages in ultra-high partitions.

In terms of performance, the glass-based Mini LED backlight can achieve the effect of HDR 1400. The display quality is more exquisite, and the halo control is better, which can bring better visual experience to users.

The LTPS drive backplane has better stability, and its high mobility ensures that the backplane can adopt an internal scheme to achieve uniformity control, achieve higher bit count design and better compensation effect. The good dimensional stability and chemical resistance of the glass-based material also give the backlight a good overall reliability.

In terms of cost, in the multi fraction zone design, the adoption of AM mode further reduces the manufacturing cost and driving cost of glass substrate, and expands the comprehensive cost advantage.

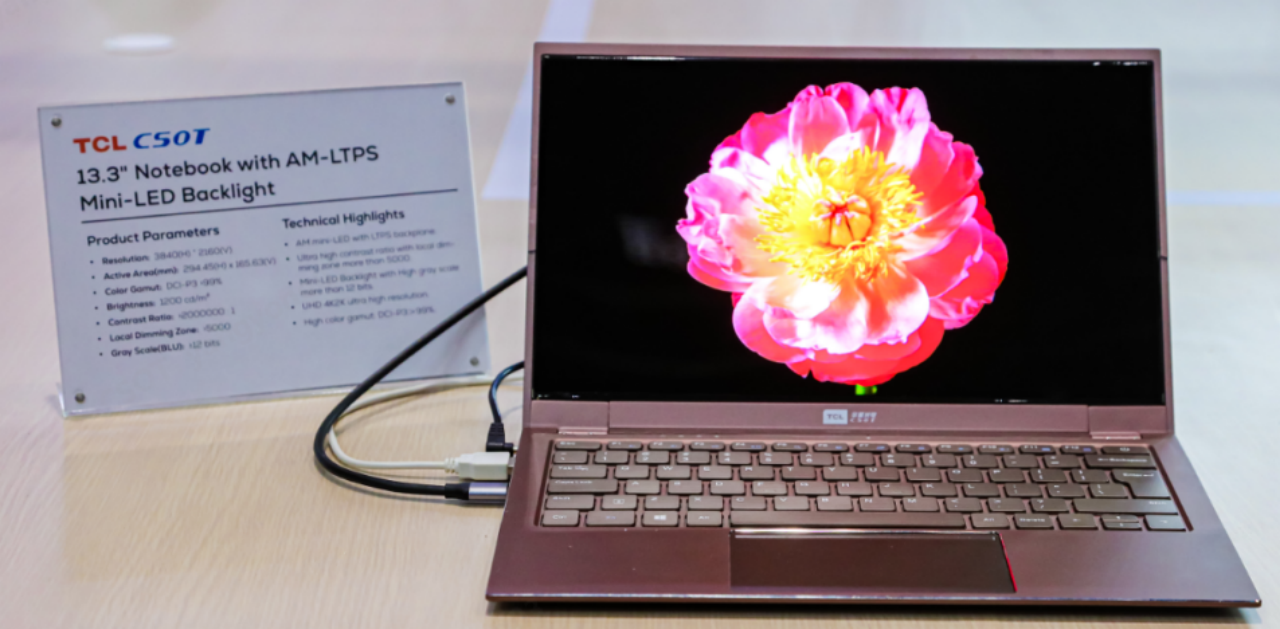

As a leading panel enterprise, TCL CSOT has a deep insight into the industry trend, and has carried out the layout of the whole industry chain early on. It has successively developed the world's first 48" AM Mini LED vehicle integrated screen with 5000+ partitions & 8bits, and 13.3" ultra-thin laptop prototype with 5000+ partitions & more than or equal to 12 bits.

48" 8K In-cell Touch AM Mini LED backlight curved vehicle screen

The vehicle integrated screen was exhibited at DTC in 2020, and recognized by the world-class car manufacturers. The 13.3" ultra-thin laptop was exhibited at SID in 2022, which was also favored by the world-class Internet companies.

13.3" AM mini-LED Backlight

TCL CSOT stands out among many outstanding technology enterprises. In addition to its leading scientific research strength and forward-looking industry insight, it is also due to its respect for technology and its insistence on innovation. In the future, TCL CSOT will continue to improve its technical layout and create a screen series matrix to bring consumers a more cutting-edge and smooth product experience.