TCL CSOT will focus on the self-produced highland of key materials, and value reconstruction for self-developed copper acid

Recently, TCL CSOT's self-developed cupric acid project has made a breakthrough progress, solved the safety problem under high copper ion concentration and the key technical bottleneck of etching rate decline, achieved the ultimate life of cupric acid of 8000ppm, and it is far beyond the industry's upper limit of 7000ppm for the high-hydrogen peroxide one-dose system. This achievement is not only expected to further reduce production costs and enhance its competitiveness, but also shows TCL CSOT's self-developed technical strength in the field of semiconductor display for core basic technologies and materials.

In recent years, with the emergence of "the biggest change in a century", guaranteeing the safety of the industrial chain has become a top priority task for China's manufacturing industry. However, the independent research of core materials is a key factor in guaranteeing the safety of the industrial chain and enhancing the competitiveness of enterprises and even the industry. As a leading enterprise in the semiconductor industry, TCL CSOT is facing increasingly severe industry status. It has begun to actively change its business thinking, promote the upgrading and optimization of procurement management mode, organize in-depth analysis and reduce costs by category structure, and propose and implement a number of key material hilltop projects, including the "copper acid self-mixing and self-research project".

Just based on the insight into the industry environment and the needs of the enterprise itself, TCL CSOT walked a long road of self-research on copper acid used for etching circuit which is a core material with high cost.

Since 2016, TCL CSOT has built its capabilities in the field of basic materials in the aspect of "formulation system establishment, fine formulation adjustment, production process development, and detection technology development", and has overcome a series of technical problems of etching characteristics. In 2016, it completed the construction of development platform and mass production platform, and in 2019, it achieved a single point breakthrough in M1 H#1 t2 single line mass production. After nearly two years of hard research, in 2020, technology upgrading will be achieved, and self-developed H#2 will achieve full line mass production of Shenzhen copper manufacturing process M1, thus becoming the first panel enterprise in the industry to successfully self-developed copper acid.

The phased victory did not make TCL CSOT's self-developed copper acid team satisfy with the current status, but embarked on the road of improving technology again. Through in-depth research on chelating agents and stabilizers, TCL CSOT's self-developed cupric acid team has successively broken through key technical bottlenecks such as safety problems under high copper ion concentration and the decline of etching rate, and made great progress in the life extension route: self-developed H#6 formula has broken through the upper limit of 8000ppm life of high hydrogen peroxide system. This is a new step for TCL CSOT's self-developed capability of materials, it not only marks the consolidation and improvement of TCL CSOT's technical strength in the field of copper acid, but also provides greater help for enterprises to reduce costs and increase efficiency.

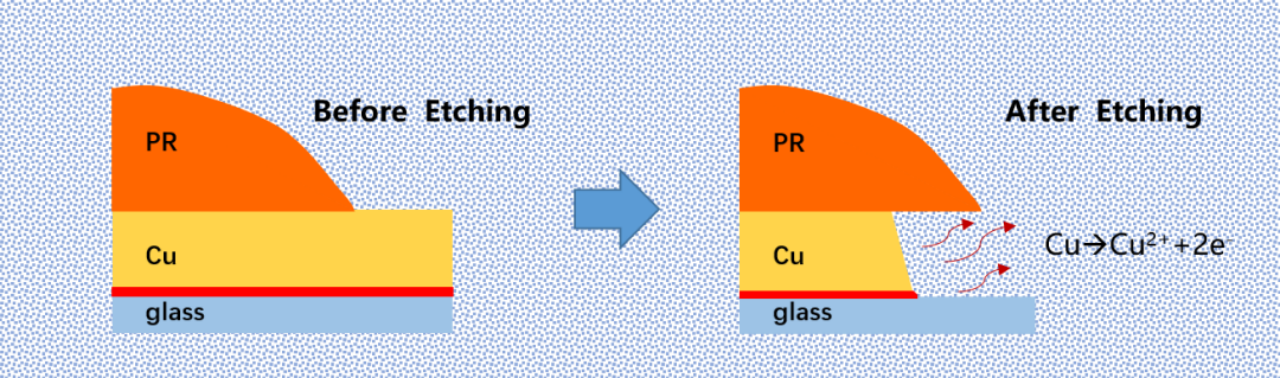

Schematic Diagram of Cupric Acid Etching

The leading achievements of TCL CSOT from scratch, from good to excellent, and then to breaking the industry ceiling benefit from TCL CSOT's high attention and investment in R&D, as well as the strong talent team that has been constantly consolidated over the years. The TCL CSOT self-developed copper acid project team is led by experienced experts, and there are many doctors and masters in the team. With a strong talent base and firm goals, the team has continued to work hard, and create a strong scientific research team with frequent good news. The project has also brought significant effects on cost reduction for enterprises. From 2020 to now, the cost of TCL CSOT copper acid has been saved a hundreds of millions of Yuan.

From the perspective of the enterprise, the success of TCL CSOT copper acid self-developed project is conducive to building the basic capacity of material formulation, ultimately develop customized products and avoid high-level products being controlled by others. From the perspective of long-term development, TCL CSOT can achieve upstream and downstream integration through innovative mode, adjust the business structure, create a material ecological chain, further realize structural cost reduction and improve profits. Finally, TCL CSOT realized its own formula intellectual property rights by means of this project, and greatly enhanced the company's technological competitiveness and discourse power in the industrial chain.

In today's deeply globalized economy, it is urgent to maintain the safety of China's industrial chain and supply chain. Especially in the context of the continued spread of the epidemic, we must pay attention to the localization of industrial chains and achieve technological self-reliance on the basis of strengthening and maintaining the stability of the global supply chain. Faced with the uncertainty of the supply chain market, TCL CSOT will continue to attach importance to the construction of industrial ecology, ensure the supply security of the domestic industrial chain, comprehensively build TCL CSOT's influence in the global semiconductor display field, and continue to make more contributions to the industry and social and economic development!